A global leader in technology, engineering, and infrastructure development, Siemens showcased an advanced FREYR Battery factory as a digitally-twinned model to audiences. The demo taps a recent partnership with computing giant NVIDIA to build use cases and adoption of the industrial metaverse.

NVIDIA debuted the model at the Hannover Messe trade show this week using its cutting-edge digital twin technologies. The demo comes after Siemens struck a partnership with FREYR to become the latter’s preferred supplier for automation technology.

The deal will provide the Lysaker, Norway-based battery firm with enhanced production and efficiency scaling tools for its operations.

The company will leverage NVIDIA’s Omniverse platform with immersive replicas of FREYR’s gigafactories. This follows announcements to jointly develop the industrial metaverse last year.

Regarding the demo, Siemens and FREYR highlighted the industrial metaverse at the world’s largest trade show in Hannover. The digital twin of the Norwegian gigafactory also incorporates operational data from the physical plant’s infrastructure for real-time accuracy. Nearly all components of the facility, including machinery, safety data, robotics, automated guided vehicles, and other details, were mapped out in the factory’s digital twin.

The Industrial Metaverse and Sustainability

According to NVIDIA, its Omniverse industrial metaverse tools will allow FREYR to boost its operations to supply “high-density, cost-effective battery cells for stationary energy storage, electric mobility and marine applications.”

The demo also revealed how disparate teams could leverage “comprehensive digital twins in the industrial metaverse” by creating current and future plant design models.

NVIDIA added in its blog post,

“Amid growing worldwide sustainability initiatives and the rapid electrification of transportation, the battery industry is projected to grow to $400 billion by 2030. Battery cell manufacturing is a critical step in the battery value chain, with manufacturers investing billions of dollars in new battery-cell plants to meet this new demand.”

FREYR can host meetings with potential investors, customers, and clients while allowing them to tour the digitally-twinned plant in Norway. During meetings, attendees can view the plant’s exterior prior to entering the physical location.

Check out the incredible journey of FREYR Battery’s Customer Qualification Plant (CQP) in Mo i Rana, Norway – from an empty hall to a state-of-the-art 13,000 m² facility ready to revolutionize battery tech 🔋⚡️

Read more about the CQP here: https://t.co/CCXvv0wGIX $FREY pic.twitter.com/NcroYH2tr8— FREYR Battery (@FREYRBattery) April 11, 2023

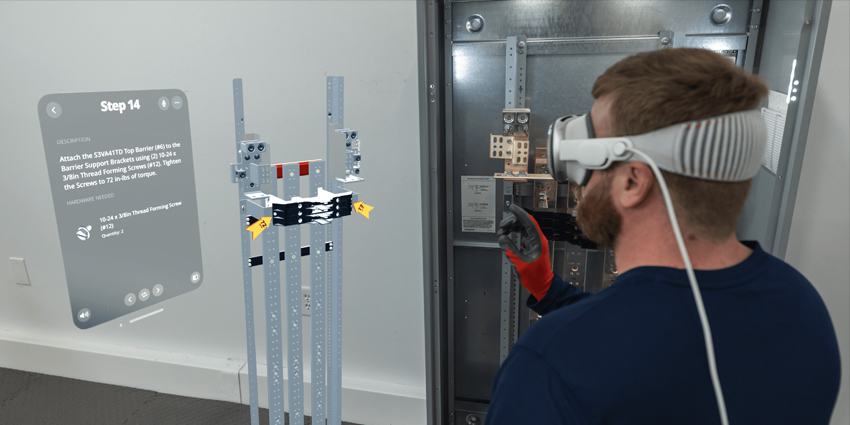

The demo also provides interior walkthroughs of the digital twin using a 1:1 ratio of the physical plant’s size and dimensions. It also offers real-time 3D (RT3D) simulations and visualisations of plant machinery and processes using the factory’s sensors and Internet of Things (IoT) technologies.

Managers can also launch Microsoft Teams meetings at manufacturing cells, where attendees can virtually teleport to locations across the digital twin. The virtual space can also provide sensory information from robots, valves, and other devices.

NVIDIA-Siemens Xcelerator Tool

The Hannover Messe demo comes months after Siemens and NVIDIA struck a partnership with the former’s Xcelerator and Omniverse 3D design tools.

Using “physics-based digital models” and artificial intelligence (AI), Siemens’ Xcelerator tool will allow firms to significantly improve their production lifecycles with cloud and edge-backed emerging technologies.

At the time, Roland Busch, President and Chief Executive, Siemens AG, said: “Photorealistic, physics-based digital twins embedded in the industrial metaverse offer enormous potential to transform our economies and industries by providing a virtual world where people can interact and collaborate to solve real-world problems”

Clients across industry verticals could see a rise in productivity and streamlined operations. He added that the joint effort would lead to a “real-time, immersive metaverse” connecting devices and software across key infrastructure.

Nokia Bell Labs and the Industrial Metaverse

Speaking in an interview with Thierry E Klein, President of Bell Labs Solutions Research, XR Today discussed how the industrial metaverse could empower verticals across the economy.

The executive from the Espoo, Finland-based firm stated the industrial metaverse would remain the driving force behind the sector’s profitability.

He said at the time,

“The manufacturing, energy, logistics, construction, and transportation sectors of our economies stand to gain the most from implementing metaverse technologies. These are the industries that serve as the backbones of our economies. Interactions between the enterprise metaverse in the front and back offices and the industrial metaverse in operational technology are inevitable”

As virtual, augmented, and mixed reality (VR/AR/MR) devices became more user-friendly in design and comfort, they would also become more affordable, allowing greater adoption rates. This would speed up the adoption of the industrial metaverse, allowing workplaces to transform digitally.

Other firms, such as Vodafone, General Electric, and others, have leveraged impressive digital twin technologies to transform their operations. The solutions provide firms with real-time data on critical infrastructure, leading to massive advancements in engineering, network management, and other vital insights.